- EN 441 stainless steel flat bar Hot rolled / cold drawn

- STS304L stainless steel round bar

- Stainless Steel Hot Rolled Flat Bar

- ISO Stainless Steel Angle Bar

- straight cut stainless steel wire sus304

- 304 bright soft annealed stainless steel wire

- 304L bright soft annealed stainless steel wire

- Stainless Steel Wire

- AISI316 stainless steel round pipe/tube

- 300 Series grade stainless steel round pipe

- AISI/SUS stainless steel pipe/tube cold drawn

- ASTM A249 stainless steel round pipe

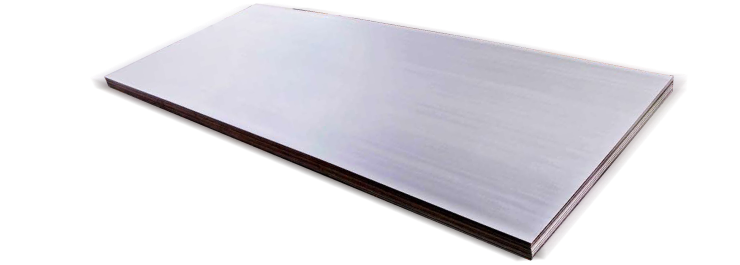

Stainless Steel Cold Rolled Sheet: Which Is Suitable For You?

Inquiries : 0 - 2017/2/7 19:17:16

In the production of steelproducts, steel is molded and reshaped with different machinery at differenttemperatures. Rolling produces flat steel sheets of a specific thickness andthe process is steel rolling involves metal stock passing through a pair ofrolls.

The classifications of Stainless Steel Cold Rolled Sheet are important and people need to understand thedifference. If the temperature of the metal is below its recrystallizationtemperature, the process is termed as cold rolling. The process is classifiedaccording to the temperature at which the metal is rolled. If the temperatureof the metal is above its recrystallization temperature, then the process istermed as hot rolling.

Hot Rolled Steel: This process removes any induced stresses andgrain deformation due to the elevated working temperature. Hot rolling is used mainly to produceproducts like sheet metal or simple cross sections, such as rail tracks and I-beams.

Cold Rolled Steel: Cold rolling helps in hardening andstrengthening the material thus improving the material¡¯s mechanicalproperties. It also improves the surfacefinish and holds tighter tolerances. Cold-rolledproducts often include similar hot rolled products like sheets and bars, butare usually smaller.

During the cooling process,non-uniformed cooling may occur, which results in residual stress of theproduct. However, room temperature StainlessSteel Cold Rolled Sheet is less malleable than hot steel, so cold rollingcannot reduce the thickness of a work piece as much as hot rolling in a singlepass.

Cold Drawn Steel: Cold drawing steel is similar to cold rollingbut instead of producing a flat object it produces steel like a coke can. Itmakes steel into the form of a wire like the spokes of a wheel or a paper clip.The room temperature steel is pulled through the die which reshapes it into athinner shape while maintaining the same volume.

Save